Plant Engineering and Machinery Division(Powder System):Double-shell, External Heating Type Rotary Kiln

Double-shell, External Heating Type Rotary Kiln

|

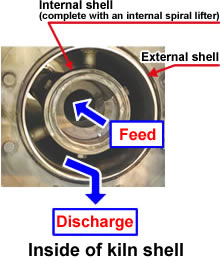

SummaryWith the recent active improvement of power functions and development of new materials, there are increasing needs not only to upgrade the performance but also to intensify the functions. In order to respond to these needs, we at KUROMOTO, which have ample time-proven accomplishments in the drying and calcining technology fields, have developed the double-shell, external heating type of rotary kiln. This rotary kiln has a double construction consisting of the internal shell and external one, displaying a variety of features. |

Features

|

|

Use

|

Outline figure

Typical Flow Sheet