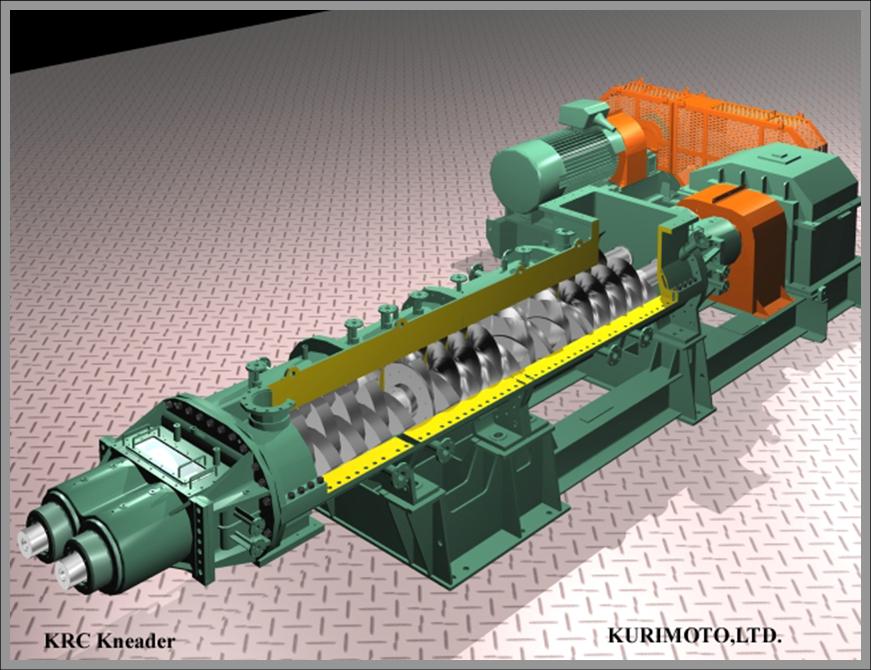

KRC Kneader -Twin Screw Continuous Kneader / Reactor-

Division for this product Plant Engineering and Machinery Division

Outline

|

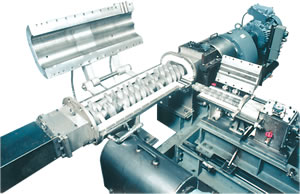

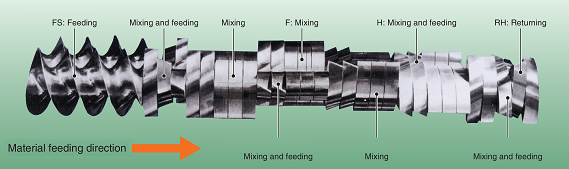

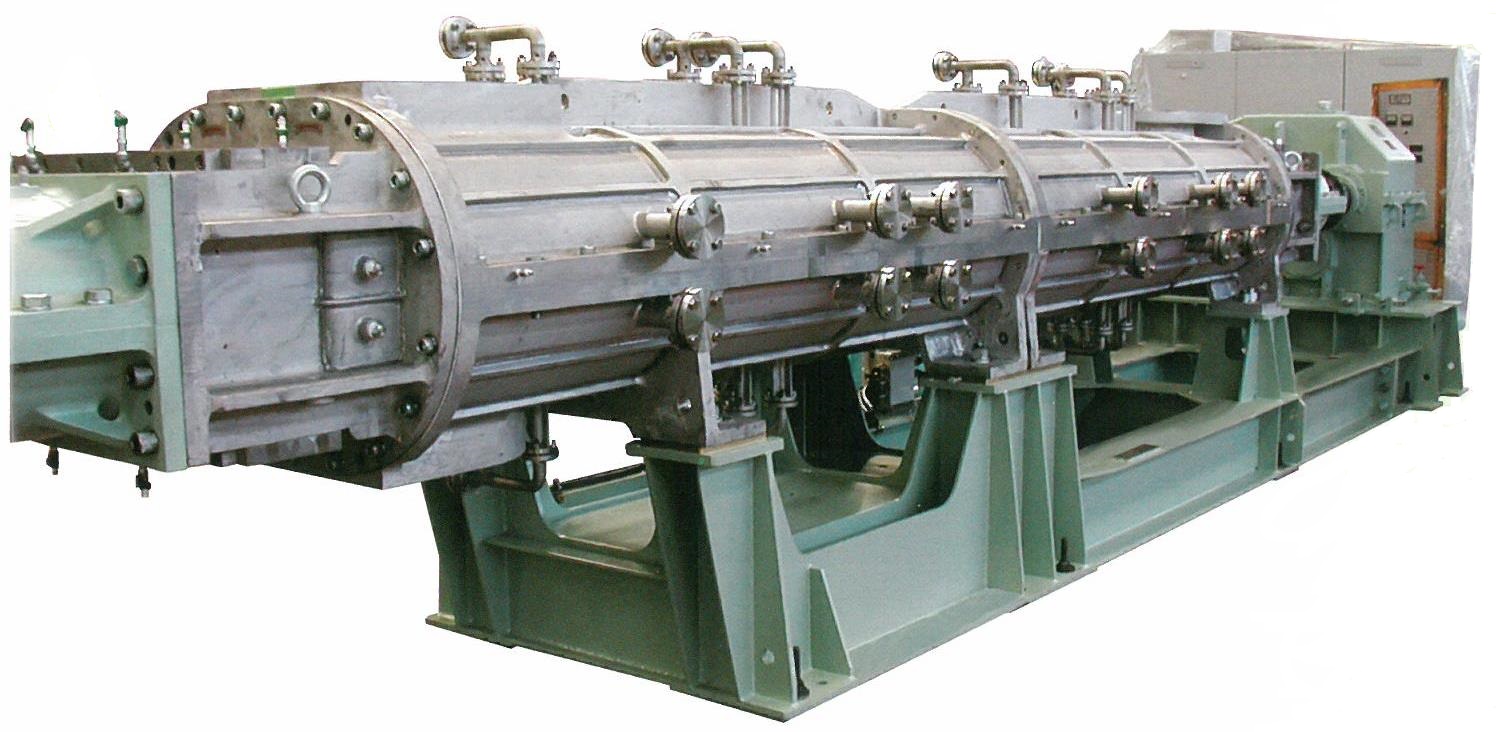

KRC Kneader is ideally suited for operations involving mixing, kneading, reaction, polymerization, crystallization, compounding and heating or cooling of materials up to many million centipoise viscosity. Kurimoto KRC Kneader is a horizontal, twin screw, closed type continuous kneading/reacting processor. KRC Kneader has more than 1,300 sets of delivery track records. And the KRC Kneader has a number of recent successful accomplishments as continuous polymerization / reacting processor for engineering plastics and others. Compared to twin screw extruder, KRC Kneader has compact structure such as short L/D and low power while having equivalent kneading and dispersion performance and contributing to rationalization of manufacturing process and cost reduction. |

Keyword

Product genre

Features

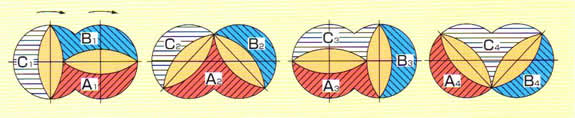

| Click here, it can be seen that screws and paddles rotate in the same direction |

Keyword

Customer topic

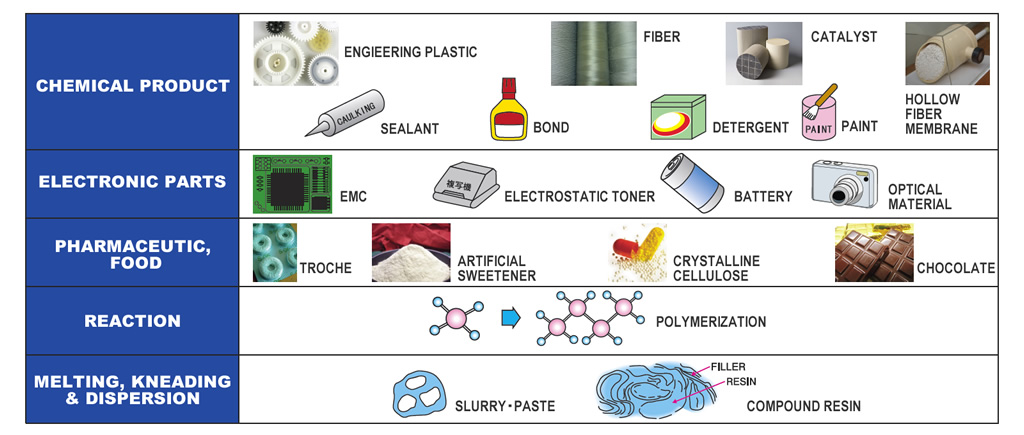

Applications

Polymerization and Reaction for Engineering Plastics ( Polyacetal, Polyamide, Polyurethane, etc.)

Kneading for Plastics (Epoxy, Polyamide, Polyester, etc.)

Kneading for Chemical Products (Sealing material, Powder Paints, etc.)

Kneading for Electric Material Products (Battery material, Ceramic, Carbon , EMC, etc.)

Lab test and pilot test can be performed. Typically in one to three days of testing, feasibility can be proven and the machine can be configured to suit the specific product and mixing needs.

Keyword

Product application

Details

Specification

S1 KRC Kneader/Reactor is ideal for R&D

Sample Flow

|

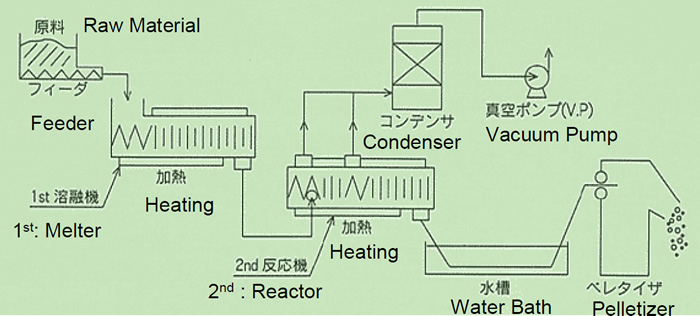

Reaction / Monomer Removal  |

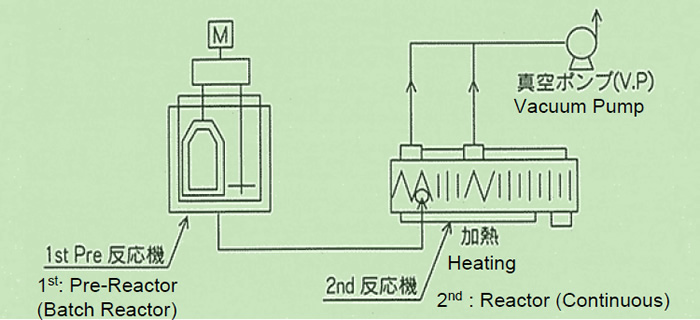

Reaction / Batch Reactor + Continuous Reactor  |

|

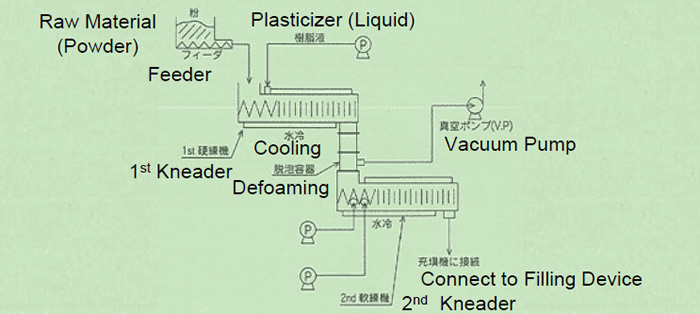

Kneading / Sealant Material  |

Others

Keyword

Applicable processes

Keyword

Applicable industries

Division for this page Plant Engineering and Machinery Division